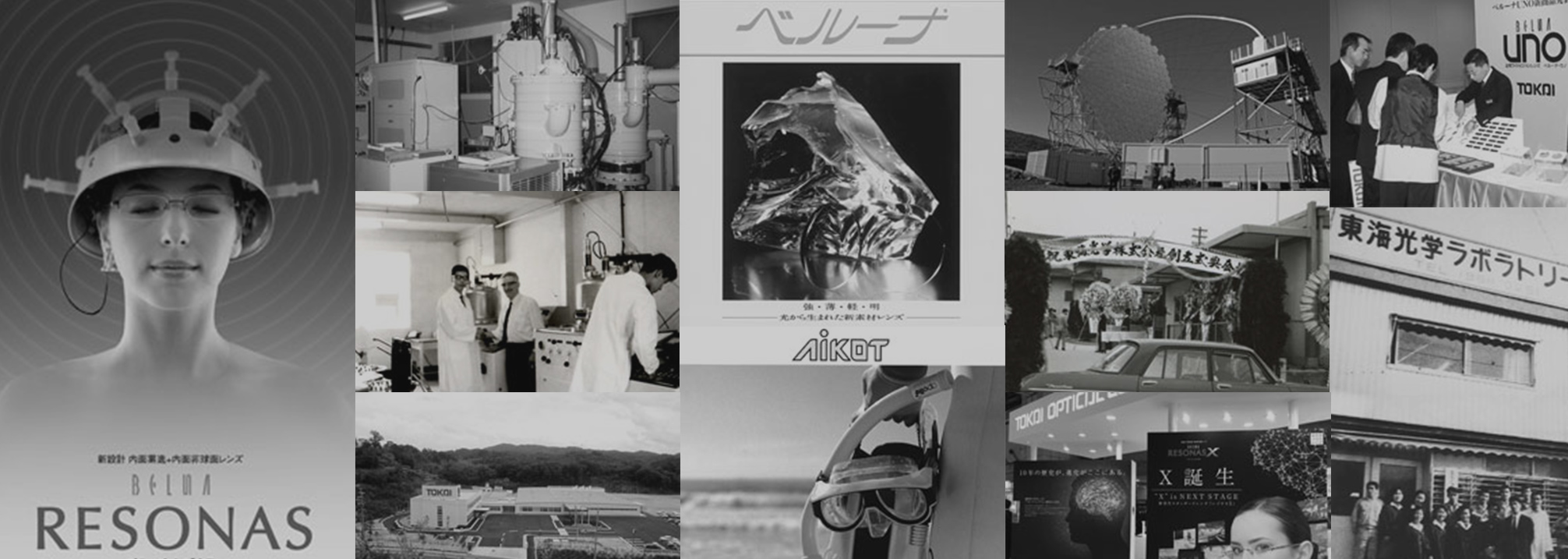

History of TOKAI OPTICAL since its founding

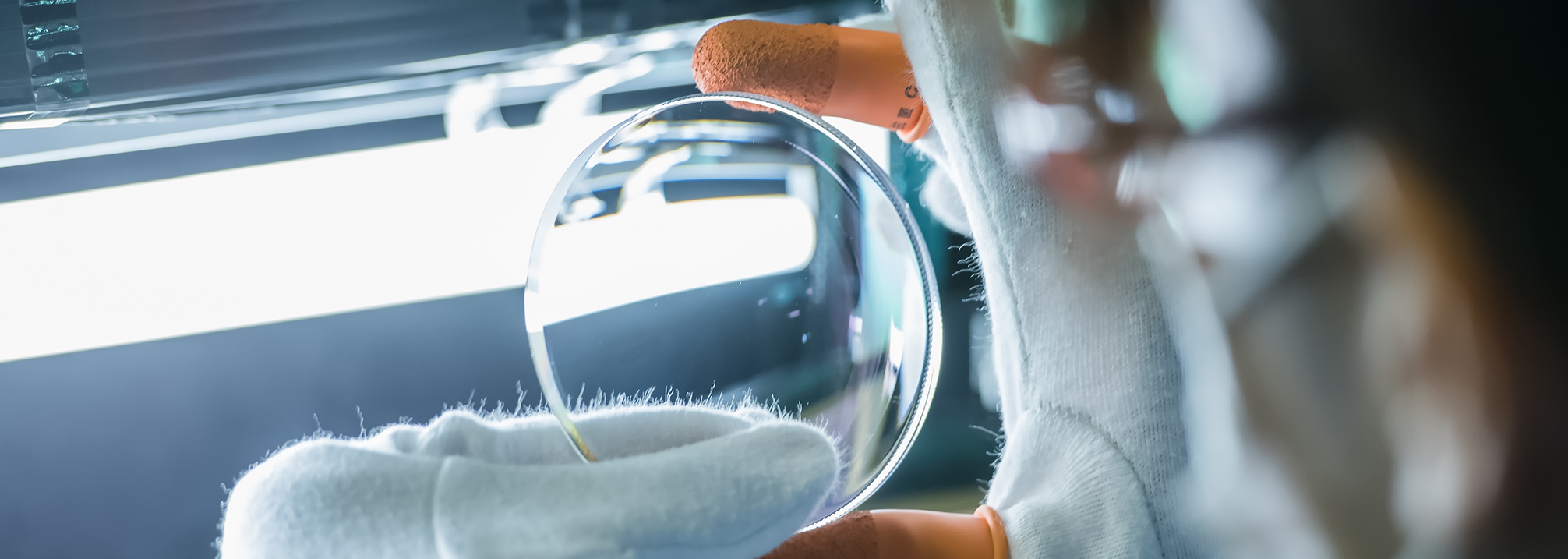

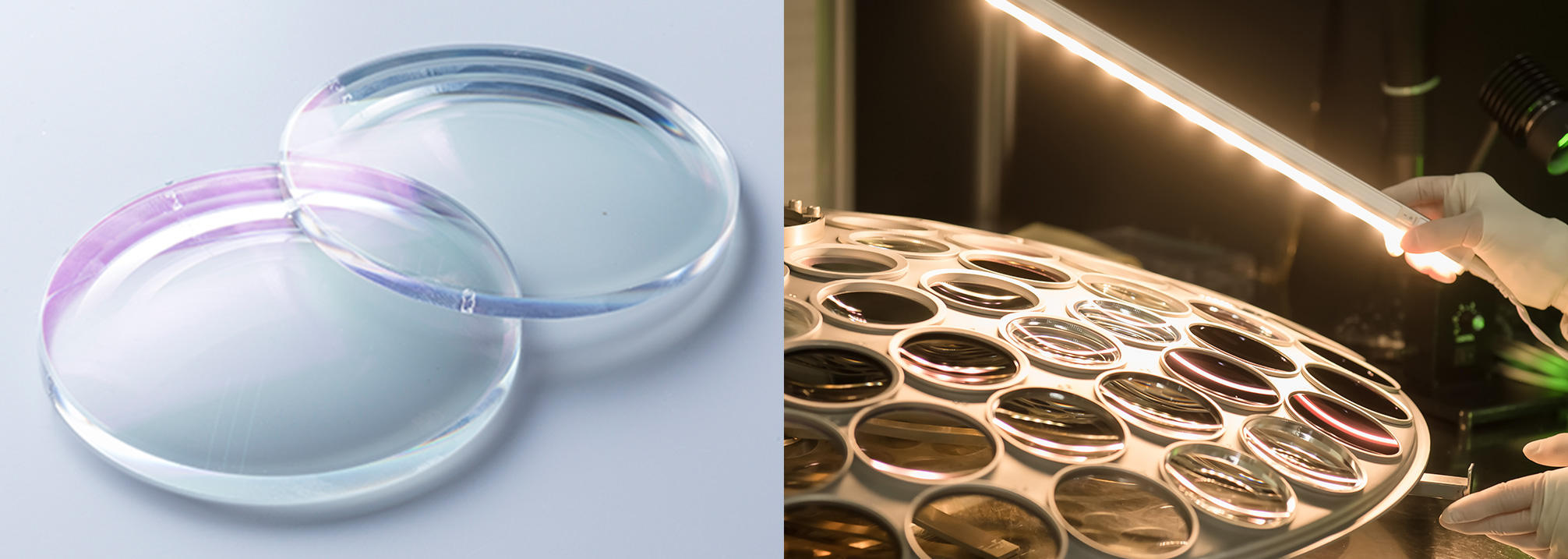

Since the birth of our company’s first eyeglass lens in 1939, TOKAI OPTICAL has responded to the advanced needs of “lighter, thinner and clearer lenses” faster than anyone else. The evolution of spectacle lens technology itself. In particular, the cutting edge lens design that supports eyeglass fashion has attracted a great deal of attention with each new product announcement and has shaped numerous trends.

Because of our pride as a manufacturer specializing in eyeglass lenses that boasts advanced technology, and our track record and confidence that we have been appreciated and loved by everyone, each and every employee is constantly working on new challenges with sincerity.