Founder Shizu Furuzawa encounters eyeglass lenses

In the first year of the Taisho era (1912-1926), the country transitioned to a modern state, and public opinion began to sway politics. The founder, Shizu Furuzawa, was born in 1911, the year before that. When he was young, he lost his mother to pneumonia, and spent his childhood struggling with pneumonia himself. The world is Taisho democracy and popular culture is flourishing, and classmates of the same generation go on to higher education and work and play an active role in society. In the midst of this, Shizu, who was delayed due to his illness, used that difficult time as a springboard to ignite his independent ambition and poured his passion into spectacle lenses.

Shizu first encountered spectacle lenses in 1927 at the age of 18 at Shimomura Lens Laboratory, which was introduced by his father. This was the first seed that led to the establishment of TOKAI OPTICAL CO.LTD. At that time, wearing glasses was a luxury for the wealthy. There were lens manufacturers in Tokyo and Osaka, but there was only one spectacle lens factory in Nagoya, this Shimomura Lens Laboratory. Since the president was a master of technology, Shimomura Lens products were highly regarded for their high quality. Shizu, who likes crafts and is good at science and mathematics, is appointed as a foreman at Shimomura Lens because of her natural craftsmanship, and she takes charge of the entire manufacturing process of eyeglass lenses.

Developed Japan’s first polishing machine for astigmatism (TC machine)

Speaking of the lens manufacturing process in the early Showa period, pressing, rough cutting, gluing, sanding, polishing, peeling, and inspection. One craftsman undertook most of this series of processes, and the craftsman completed the process until just before the inspection. The finish of the lens depends on the skill of the person, and even a skilled craftsman can only make nine astigmatic lenses a day. The production system was far from efficient and mass production. Shizu wondered if there was any way to create an efficient manufacturing method, and immediately began research on manufacturing machines for astigmatic lenses. At the end of the day’s work, he read through books with items on “glasses” and “lenses.” And one day he found a model of a lens polishing machine. Shizu, who saw it, will devote himself to machine development from the next day. Mrs. Shimomura, the president’s wife, readily consented to the development and supported it.

Speaking of the lens manufacturing process in the early Showa period, pressing, rough cutting, gluing, sanding, polishing, peeling, and inspection. One craftsman undertook most of this series of processes, and the craftsman completed the process until just before the inspection. The finish of the lens depends on the skill of the person, and even a skilled craftsman can only make nine astigmatic lenses a day. The production system was far from efficient and mass production. Shizu wondered if there was any way to create an efficient manufacturing method, and immediately began research on manufacturing machines for astigmatic lenses. At the end of the day’s work, he read through books with items on “glasses” and “lenses.” And one day he found a model of a lens polishing machine. Shizu, who saw it, will devote himself to machine development from the next day. Mrs. Shimomura, the president’s wife, readily consented to the development and supported it.

Development was extremely difficult. Polishing machines for astigmatic lenses require curved polishing that differs from spherical lenses, requiring high-precision processing technology. One year passed, two years passed, and finally, in the third year, we were able to produce something with satisfactory quality. Finally, with the completion of an astigmatism polishing machine (TC machine), it became possible to mass-produce 110 lenses in 4 hours of polishing, and 220 lenses in 2 rotations per day. At that time, Shizu was 23 years old. The events of that day were deeply engraved in Shizu’s personal history as the greatest achievement of his life.

Establishment of “Furuzawa Lens Factory”

The astigmatism grinder developed by Shizu became well-known within the industry, and soon other manufacturers in the same industry manufactured similar machines. The mass production system boosted domestic demand, and exports also flourished. Shizu’s passion for lenses really moved the domestic and overseas markets.

Eleven years after joining Shimomura Lens Research Institute, Shizu Furuzawa decided to go independent. Her younger brother, Masao, who joined Shimomura Lens Laboratory later, left the company at the same time. In 1939, Shizu and Masao founded the Furuzawa Lens Factory in Mukoda-cho, Naka-ku, Nagoya. In consideration of coexistence with Shimomura Lens Research Institute, we decided not to manufacture astigmatic lenses, but focused on manufacturing spherical lenses. In addition, Shizu adopted an assembly-line process that divided the manufacturing process, which was rare among lens manufacturers at the time. In view of the situation of the Sino-Japanese War, the system was designed to take the initiative in dealing with future shortages of skilled craftsmen. Furuzawa Lens decided to supply products to retail stores in and outside of Nagoya city, with a reliable eye for quality that he had trained at Shimomura Lens Research Institute and a reputation that “Shizu’s work has a strict delivery schedule.”

By the way, during the Pacific War that broke out in 1941, Nagoya, where the munitions industry was located, was in a situation where bombing could occur at any time. Meanwhile, Shizu will be evacuated from Nagoya to Okazaki. The Furuzawa lens factory was temporarily closed, and in 1944, he joined the joint venture “Nitto Kogaku Co., Ltd.” in Okazaki City. At a time when it was difficult to obtain machine parts and product materials, Shizu and Masao worked together to build a factory. However, in 1945, a B29 incendiary bomb fell on the city of Okazaki and Nitto Kogaku burned down. The war ended on August 15th of the same year. Shizu and Masao survived the war, but they started from scratch again. There was no time left to mourn the end of the war, and the two of them burned with a new fighting spirit. “Let’s start our own company again and make lenses.” Thus, Furuzawa Lens Factory set sail for a new era.

Incorporation and Road to AJOC Designated Factory

In 1947, Masao became independent as “Masao Furuzawa Lens Factory”. At that time, Shizu specialized in manufacturing lenses for astigmatism and Masao specialized in manufacturing spherical lenses. In the post-war era of material shortages, the voices of people waiting for spectacle lenses did not stop.

In October 1957, Shizu established Koyo Kogaku Co., Ltd., and in December of the same year, Masao established Shochiku Kogaku Co., Ltd. Establish a company form as a corporation and create a production system with inventory. As a result, retailers no longer need to hold inventories, and manufacturers have a wholesale function, which is very useful for retailers’ capital efficiency. The inventory policy also brings new opportunities for Shizu and Masao. In 1958, it was selected as a designated factory for joint purchasing of the ALL JAPAN OPTICAL CHAIN (commonly known as AJOC), the industry’s first voluntary chain consisting of seven optical stores. This was due to their inventory policy as well as their overwhelming trust in the quality of the lenses made by the Furuzawa Brothers. Two types of lenses, the “Lumy lens” and the “collector lens,” were released, and the number of orders rapidly increased. In 1964, the Tokyo branch office was opened for quick delivery. In the same year, a branch office in Kyushu was also opened, securing a distribution base for the whole country.

In October 1957, Shizu established Koyo Kogaku Co., Ltd., and in December of the same year, Masao established Shochiku Kogaku Co., Ltd. Establish a company form as a corporation and create a production system with inventory. As a result, retailers no longer need to hold inventories, and manufacturers have a wholesale function, which is very useful for retailers’ capital efficiency. The inventory policy also brings new opportunities for Shizu and Masao. In 1958, it was selected as a designated factory for joint purchasing of the ALL JAPAN OPTICAL CHAIN (commonly known as AJOC), the industry’s first voluntary chain consisting of seven optical stores. This was due to their inventory policy as well as their overwhelming trust in the quality of the lenses made by the Furuzawa Brothers. Two types of lenses, the “Lumy lens” and the “collector lens,” were released, and the number of orders rapidly increased. In 1964, the Tokyo branch office was opened for quick delivery. In the same year, a branch office in Kyushu was also opened, securing a distribution base for the whole country.

Brothers Shizu and Masao, although they manufacture different lenses, have the same customers and suppliers, and have always worked together to exchange information, such as important business negotiations. It would not be an exaggeration to say that they have played a vital role in driving the spectacle lens market. And in 1965, the two decided to become the two wheels of the company both in name and reality. He founded “TOKAI OPTICAL CO., LTD.” to develop the company further by joining forces. Shizu Furuzawa, President and Representative Director, Masao Furuzawa, Executive Managing Director. The two brothers and about 100 employees steered the challenge to the new spectacle lens market with one mind. After that, TOKAI OPTICAL CO.,LTD. achieved rapid development.

Brothers Shizu and Masao, although they manufacture different lenses, have the same customers and suppliers, and have always worked together to exchange information, such as important business negotiations. It would not be an exaggeration to say that they have played a vital role in driving the spectacle lens market. And in 1965, the two decided to become the two wheels of the company both in name and reality. He founded “TOKAI OPTICAL CO., LTD.” to develop the company further by joining forces. Shizu Furuzawa, President and Representative Director, Masao Furuzawa, Executive Managing Director. The two brothers and about 100 employees steered the challenge to the new spectacle lens market with one mind. After that, TOKAI OPTICAL CO.,LTD. achieved rapid development.

In 1965, following the relocation of the Tokyo office and the opening of the Kyushu branch office, the Nagoya office was opened in Shirakabe-cho, Nagoya. It was the first base after the merger as TOKAI OPTICAL CO.,LTD. TOKAI OPTICAL’s first laboratory, the Nagoya Laboratory, is located on the first floor of a two-story wooden building. Here, the system for custom-made products such as bifocal lenses and custom-made lenses, which are difficult to mass-produce, was established.

In 1965, following the relocation of the Tokyo office and the opening of the Kyushu branch office, the Nagoya office was opened in Shirakabe-cho, Nagoya. It was the first base after the merger as TOKAI OPTICAL CO.,LTD. TOKAI OPTICAL’s first laboratory, the Nagoya Laboratory, is located on the first floor of a two-story wooden building. Here, the system for custom-made products such as bifocal lenses and custom-made lenses, which are difficult to mass-produce, was established. The first job that Takeo tackled after joining the company was the development and sales of coated lenses. A coated lens is a lens in which a special substance is added to the surface of the lens to reduce light reflection and increase transmittance compared to a normal lens. In 1967, TOKAI OPTICAL decided to start manufacturing coated lenses. For the first time in Japan, we introduced two full-scale coating machines (vacuum deposition equipment) from Italy into the Kamoda Factory. Takeo also turned his attention to the GLAR vacuum deposition system. I bought 4 of these. Takeo was in his second year at the company at the time. He spares no money for a challenge. He fearlessly pushes forward with innovation. What Shizu and Takeo had in common was their insatiable desire to pursue their dreams.

The first job that Takeo tackled after joining the company was the development and sales of coated lenses. A coated lens is a lens in which a special substance is added to the surface of the lens to reduce light reflection and increase transmittance compared to a normal lens. In 1967, TOKAI OPTICAL decided to start manufacturing coated lenses. For the first time in Japan, we introduced two full-scale coating machines (vacuum deposition equipment) from Italy into the Kamoda Factory. Takeo also turned his attention to the GLAR vacuum deposition system. I bought 4 of these. Takeo was in his second year at the company at the time. He spares no money for a challenge. He fearlessly pushes forward with innovation. What Shizu and Takeo had in common was their insatiable desire to pursue their dreams. “Developing new products that meet the needs of our customers.” Based on this conviction, Takeo, who was the sales manager, started a new challenge. In 1969, TOKAI OPTICAL decided to sell a progressive lens (progressive lens) “ZOOM”. At that time, only TOKAI OPTICAL’s “ZOOM” and one other company had progressive lenses in the domestic market.

“Developing new products that meet the needs of our customers.” Based on this conviction, Takeo, who was the sales manager, started a new challenge. In 1969, TOKAI OPTICAL decided to sell a progressive lens (progressive lens) “ZOOM”. At that time, only TOKAI OPTICAL’s “ZOOM” and one other company had progressive lenses in the domestic market. 1972 was also the year when the organizational strength of TOKAI OPTICAL was strengthened, and the management philosophy and policies were set out. The company made a new start with an organizational structure that strongly reflected the belief of Takeo, the sales manager, who said, “Put the customer first, act with the customer, and grow together with the customer.” While promoting modern management, we introduced a facsimile machine in 1976 and a computer the following year, building the industry’s first order-receiving network. A system of “24-hour delivery system 1DAY service” is created. “How can we continue to provide services that put our hearts into them?” This thought led to the creation of a unique service that was ahead of the industry.

1972 was also the year when the organizational strength of TOKAI OPTICAL was strengthened, and the management philosophy and policies were set out. The company made a new start with an organizational structure that strongly reflected the belief of Takeo, the sales manager, who said, “Put the customer first, act with the customer, and grow together with the customer.” While promoting modern management, we introduced a facsimile machine in 1976 and a computer the following year, building the industry’s first order-receiving network. A system of “24-hour delivery system 1DAY service” is created. “How can we continue to provide services that put our hearts into them?” This thought led to the creation of a unique service that was ahead of the industry. In 1979, Masao Furuzawa became president, Shizu became chairman, and Takeo became senior managing director. As the demand for plastic lenses increased within the industry, TOKAI OPTICAL was preparing to start not only processing but also manufacturing plastic lenses. At that time, in 1981, we formed a formal business alliance with Sunlux Co., Ltd., one of the few companies in Japan capable of manufacturing plastic lenses. This was also the turning point for TOKAI OPTICAL. It is a small factory in Sabae City, Fukui Prefecture with about 20 employees, and although it has all the equipment and equipment, it still needs to be improved in terms of management and lens quality. First and foremost, it was necessary to create a relationship between management and employees. Good products cannot be created without a good relationship of trust. It took about 9 months before production of plastic lenses for the domestic market got on track. Finally, it became possible to maintain quality that is not embarrassing as a TOKAI OPTICAL lens.

In 1979, Masao Furuzawa became president, Shizu became chairman, and Takeo became senior managing director. As the demand for plastic lenses increased within the industry, TOKAI OPTICAL was preparing to start not only processing but also manufacturing plastic lenses. At that time, in 1981, we formed a formal business alliance with Sunlux Co., Ltd., one of the few companies in Japan capable of manufacturing plastic lenses. This was also the turning point for TOKAI OPTICAL. It is a small factory in Sabae City, Fukui Prefecture with about 20 employees, and although it has all the equipment and equipment, it still needs to be improved in terms of management and lens quality. First and foremost, it was necessary to create a relationship between management and employees. Good products cannot be created without a good relationship of trust. It took about 9 months before production of plastic lenses for the domestic market got on track. Finally, it became possible to maintain quality that is not embarrassing as a TOKAI OPTICAL lens. At the same time, in 1981, a new machine was installed in a corner of the Kamoda Factory. This is the first multi-coating machine for plastic lenses. As usual, this machine is not immediately usable. The engineers repeated the tests many times, and by accumulating their own know-how, TOKAI OPTICAL established a system that allowed them to sell multi-coated plastic lenses. Each of these experiences has become the spirit and technological strength of research and development that lives on at TOKAI OPTICAL. At that time, sales of plastic lenses had risen to 20% of the company’s share. In 1982, we built a new factory dedicated to plastics on land in Hina-cho, Okazaki City, in view of future demand. In this way, the production system for TOKAI OPTICAL’s original lenses was established.

At the same time, in 1981, a new machine was installed in a corner of the Kamoda Factory. This is the first multi-coating machine for plastic lenses. As usual, this machine is not immediately usable. The engineers repeated the tests many times, and by accumulating their own know-how, TOKAI OPTICAL established a system that allowed them to sell multi-coated plastic lenses. Each of these experiences has become the spirit and technological strength of research and development that lives on at TOKAI OPTICAL. At that time, sales of plastic lenses had risen to 20% of the company’s share. In 1982, we built a new factory dedicated to plastics on land in Hina-cho, Okazaki City, in view of future demand. In this way, the production system for TOKAI OPTICAL’s original lenses was established. In 1984, a continuous coating machine was installed at the Hina Factory. Until now, the batch method was used to replace the lens each time, but the fully automatic vacuum multi-layer deposition equipment, which performs a series of processes from heating to vacuum, deposition, and slow cooling, has greatly increased the speed. In addition, hard-coating equipment for plastic lenses was introduced, and productivity increased dramatically.

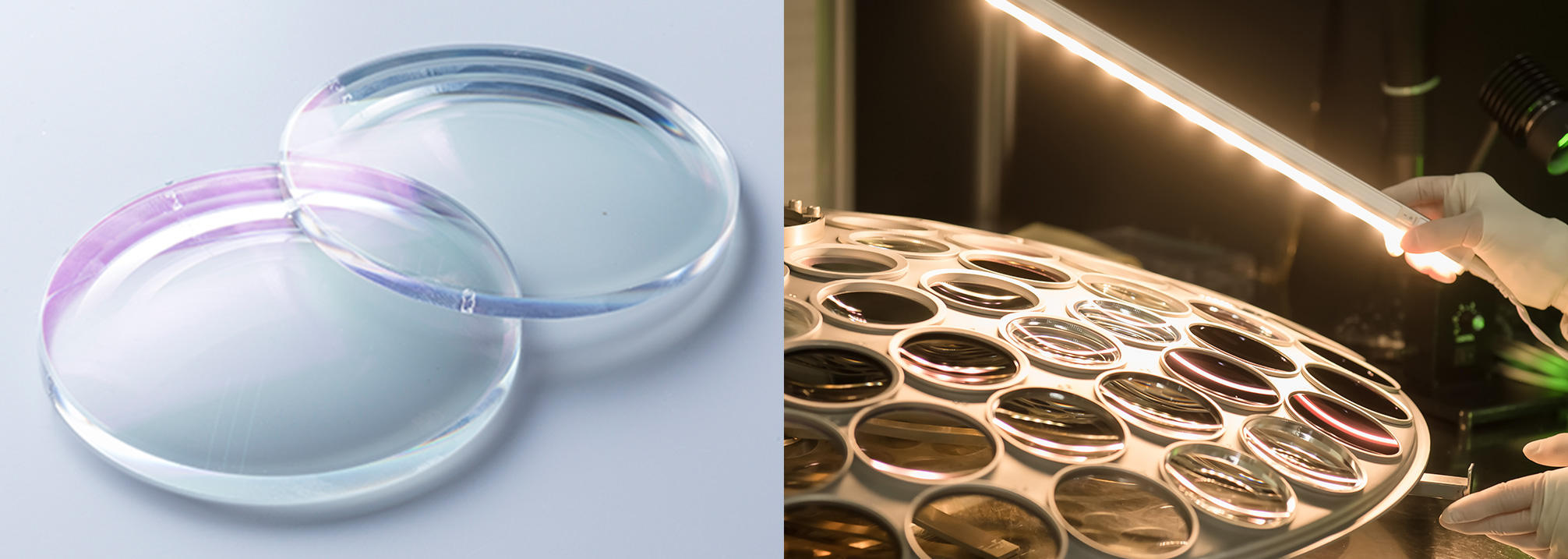

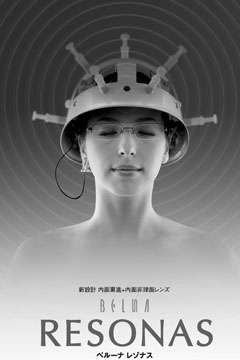

In 1984, a continuous coating machine was installed at the Hina Factory. Until now, the batch method was used to replace the lens each time, but the fully automatic vacuum multi-layer deposition equipment, which performs a series of processes from heating to vacuum, deposition, and slow cooling, has greatly increased the speed. In addition, hard-coating equipment for plastic lenses was introduced, and productivity increased dramatically. As the development of plastic lenses progressed, TOKAI OPTICAL was forced to shift from being an optical manufacturer of inorganic glass lenses to an organic chemical manufacturer. Under such circumstances, we teamed up with Showa Denko, a general chemical manufacturer. TOKOAI OPTICAL and Showa Denko started joint development based on the idea of using Slapin resin, a photo-curing resin that hardens when exposed to light, for spectacle lenses. In 1984, as part of the launch of the “Sunlux Production Technology Development Project,” we proceeded with research and development. A patent is filed for the lens manufacturing method. Development continued thereafter, and in 1987, the “Beluna” was released. The development of Slapin resin is the first in the world. Its advantage is that it is scratch-resistant and thin, and its refractive index is as high as 1.53, compared to CR-39’s 1.50. And the transparency was as high as that of glass. It also has the advantages of glass lenses, such as small chromatic aberration and low internal distortion, making it a well-balanced spectacle lens product that combines the advantages of both plastic and glass lenses. This joint development further strengthened our technological capabilities and was a great advantage for TOKAI OPTICAL.

As the development of plastic lenses progressed, TOKAI OPTICAL was forced to shift from being an optical manufacturer of inorganic glass lenses to an organic chemical manufacturer. Under such circumstances, we teamed up with Showa Denko, a general chemical manufacturer. TOKOAI OPTICAL and Showa Denko started joint development based on the idea of using Slapin resin, a photo-curing resin that hardens when exposed to light, for spectacle lenses. In 1984, as part of the launch of the “Sunlux Production Technology Development Project,” we proceeded with research and development. A patent is filed for the lens manufacturing method. Development continued thereafter, and in 1987, the “Beluna” was released. The development of Slapin resin is the first in the world. Its advantage is that it is scratch-resistant and thin, and its refractive index is as high as 1.53, compared to CR-39’s 1.50. And the transparency was as high as that of glass. It also has the advantages of glass lenses, such as small chromatic aberration and low internal distortion, making it a well-balanced spectacle lens product that combines the advantages of both plastic and glass lenses. This joint development further strengthened our technological capabilities and was a great advantage for TOKAI OPTICAL. In 1984, TOKAI OPTICAL started the Frame Division. One of Takeo’s declarations was to create a new business axis. Furthermore, in 1986, the online system “Meganet” that connects eyeglass shops and manufacturers started. It is a joint ordering system by six manufacturers including TOKAI OPTICAL, Hattori Seiko, Pentax/Carl Zeiss, Topcon, Toray, and Teijin Lens. The stance of continuing to take on new challenges is the driving force behind TOKAI OPTICAL’s leap forward. In 1987, TOKAI OPTICAL applied for the acquisition of 10,000 tsubo of land for a new factory in the mechatronics complex in Hanazonocho, Okazaki City. On May 17, 1990, the headquarters factory was completed. “We did not relocate simply for the purpose of expanding the factory, but as a general eyewear manufacturer, based on 21st-century eyewear manufacturing, we have enhanced our service system for customers, conserved the environment in the local community, and improved the working environment, including employee welfare. , We will renew the image of TOKAI OPTICAL by enhancing the functions of the head office.” Another dream of TOKAI OPTICAL began to move with a new sound.

In 1984, TOKAI OPTICAL started the Frame Division. One of Takeo’s declarations was to create a new business axis. Furthermore, in 1986, the online system “Meganet” that connects eyeglass shops and manufacturers started. It is a joint ordering system by six manufacturers including TOKAI OPTICAL, Hattori Seiko, Pentax/Carl Zeiss, Topcon, Toray, and Teijin Lens. The stance of continuing to take on new challenges is the driving force behind TOKAI OPTICAL’s leap forward. In 1987, TOKAI OPTICAL applied for the acquisition of 10,000 tsubo of land for a new factory in the mechatronics complex in Hanazonocho, Okazaki City. On May 17, 1990, the headquarters factory was completed. “We did not relocate simply for the purpose of expanding the factory, but as a general eyewear manufacturer, based on 21st-century eyewear manufacturing, we have enhanced our service system for customers, conserved the environment in the local community, and improved the working environment, including employee welfare. , We will renew the image of TOKAI OPTICAL by enhancing the functions of the head office.” Another dream of TOKAI OPTICAL began to move with a new sound. Dare to do something new that will power your company. At TOKAI OPTICAL, where such intentions flow unbroken, the “i Division” was launched during the second medium-term plan. What I worked on was the “Aikot Department,” which handles the “Aikot” brand of sports lenses such as prescription lenses for diving. The next business was the “iCS Department,” which undertakes multi-coating. Introduced two multi-coating machines to the Hina Factory for new products that make use of TOKAI OPTICAL’s vacuum deposition technology. This lens spread to domestic and overseas sales networks through trading companies. In addition, we launched a “medical eyeglass department” to establish a new field from a medical perspective.

Dare to do something new that will power your company. At TOKAI OPTICAL, where such intentions flow unbroken, the “i Division” was launched during the second medium-term plan. What I worked on was the “Aikot Department,” which handles the “Aikot” brand of sports lenses such as prescription lenses for diving. The next business was the “iCS Department,” which undertakes multi-coating. Introduced two multi-coating machines to the Hina Factory for new products that make use of TOKAI OPTICAL’s vacuum deposition technology. This lens spread to domestic and overseas sales networks through trading companies. In addition, we launched a “medical eyeglass department” to establish a new field from a medical perspective. I don’t mind taking on difficult challenges. This is the underlying strength of the progressive lens developers that TOKAI OPTICAL boasts. I started studying aspherical lenses in 1990, and continued to challenge development with the processing department of the Kamoda factory. The aspherical lens (Beluna HI-AS MC

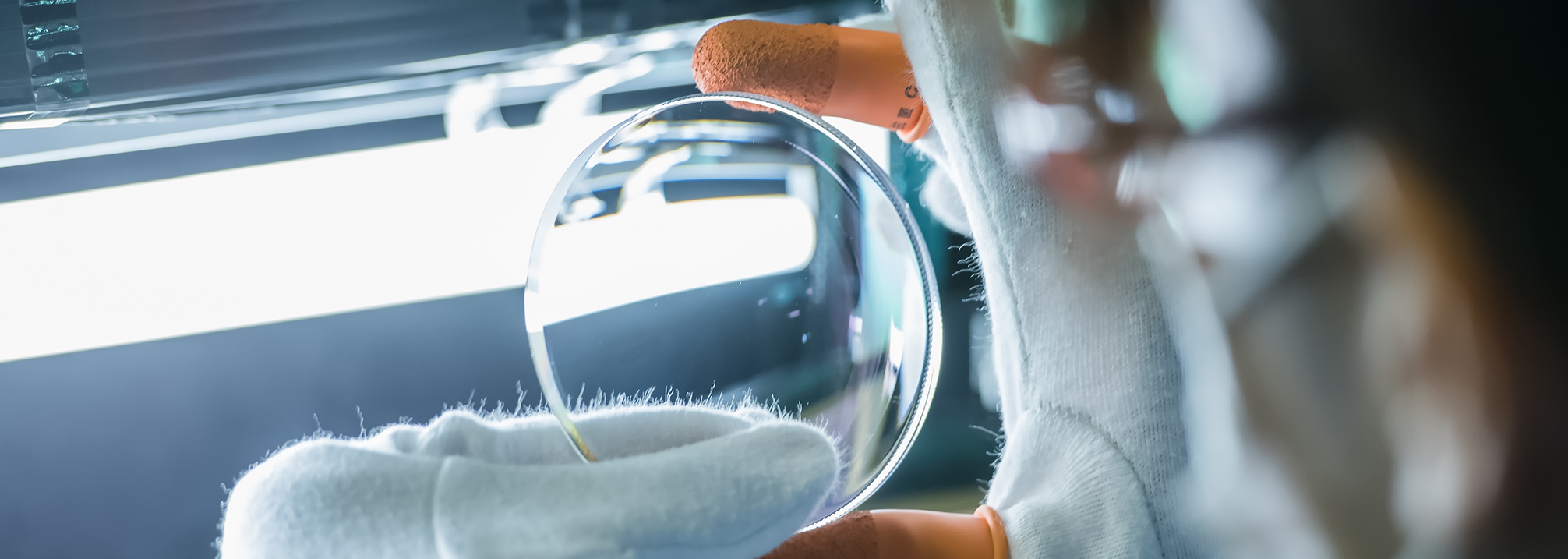

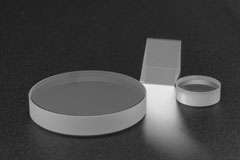

I don’t mind taking on difficult challenges. This is the underlying strength of the progressive lens developers that TOKAI OPTICAL boasts. I started studying aspherical lenses in 1990, and continued to challenge development with the processing department of the Kamoda factory. The aspherical lens (Beluna HI-AS MC TOKAI OPTICAL’s vapor deposition technology has a long track record of coating glass lenses. Optical thin film, on the other hand, is a technology that increases light transmittance and reflectance by vacuum-depositing a thin film on the surface of an object such as glass or resin. It has the functions of preventing reflection of light, removing infrared rays, and controlling light wavelengths, and its application range is wide, including cameras, televisions, personal computers, mobile phones, car navigation systems, etc., in addition to eyeglasses. However, it is technically extremely difficult. In the case of spectacle lenses, there are 3 to 5 layers to be vapor-deposited, but in the case of optical filters, there are about 40 layers, which requires nano-order thin film technology. The technology gained a good reputation, and two years after the establishment of the Thin Film Department, it was promoted to the “Thin Film Division.”

TOKAI OPTICAL’s vapor deposition technology has a long track record of coating glass lenses. Optical thin film, on the other hand, is a technology that increases light transmittance and reflectance by vacuum-depositing a thin film on the surface of an object such as glass or resin. It has the functions of preventing reflection of light, removing infrared rays, and controlling light wavelengths, and its application range is wide, including cameras, televisions, personal computers, mobile phones, car navigation systems, etc., in addition to eyeglasses. However, it is technically extremely difficult. In the case of spectacle lenses, there are 3 to 5 layers to be vapor-deposited, but in the case of optical filters, there are about 40 layers, which requires nano-order thin film technology. The technology gained a good reputation, and two years after the establishment of the Thin Film Department, it was promoted to the “Thin Film Division.” Hirokazu, the current president, joined the company in April 1994. After completing overseas inspection training and factory training, he was assigned to the sales department, and in 1999, he became the director of the president’s office. The following year, when President Takeo was about to turn 60, he started Furuzawa Juku as a place to pass down the DNA of the next generation of leaders. In addition, the 5th medium-term management plan was started by project members led by Hirokazu. Under the policy of “creating new corporate value based on thorough customer consideration and becoming a global company,” we have adopted a “market-oriented approach,” “improvement of added value,” “implementation of speedy management,” and “prompt and accurate management.” We have renewed our determination to create new corporate value, such as the ability to respond effectively. In this way, preparations to succeed TOKAI OPTICAL proceeded steadily. One of the three pillars of our long-term vision is to “expand the market beyond Japan to the rest of the world and carry out global sales development.” In order to put this into practice, we also focused on overseas expansion. In 2000, the “Overseas Division” was established along with the strengthening of the thin film business.

Hirokazu, the current president, joined the company in April 1994. After completing overseas inspection training and factory training, he was assigned to the sales department, and in 1999, he became the director of the president’s office. The following year, when President Takeo was about to turn 60, he started Furuzawa Juku as a place to pass down the DNA of the next generation of leaders. In addition, the 5th medium-term management plan was started by project members led by Hirokazu. Under the policy of “creating new corporate value based on thorough customer consideration and becoming a global company,” we have adopted a “market-oriented approach,” “improvement of added value,” “implementation of speedy management,” and “prompt and accurate management.” We have renewed our determination to create new corporate value, such as the ability to respond effectively. In this way, preparations to succeed TOKAI OPTICAL proceeded steadily. One of the three pillars of our long-term vision is to “expand the market beyond Japan to the rest of the world and carry out global sales development.” In order to put this into practice, we also focused on overseas expansion. In 2000, the “Overseas Division” was established along with the strengthening of the thin film business. In 1991, in addition to collecting information on European sales channels at the “Optica Exhibition” held in Cologne, Germany, and the “MIDO Exhibition (MIDO)” held in Milan, Italy, “refractive index 1.60” was also introduced in Europe. Well received. TOKAI OPTICAL’s quality was certainly appreciated by the overseas market. After that, he continued to connect with world-famous eyewear stores and laboratories through trading companies, and in 1995 established a joint venture, TOKAI OPTECS NV, with Belgium as the base of its global network.

In 1991, in addition to collecting information on European sales channels at the “Optica Exhibition” held in Cologne, Germany, and the “MIDO Exhibition (MIDO)” held in Milan, Italy, “refractive index 1.60” was also introduced in Europe. Well received. TOKAI OPTICAL’s quality was certainly appreciated by the overseas market. After that, he continued to connect with world-famous eyewear stores and laboratories through trading companies, and in 1995 established a joint venture, TOKAI OPTECS NV, with Belgium as the base of its global network. In April 2006, the world’s first and highest refractive index of 1.76 single focal plastic lens “Beluna ZX-AS” was released. In June of the same year, the world’s thinnest lens “Beluna ZX-MU” was released, attracting attention both in Japan and overseas. Both were extremely difficult to develop, but their high quality was enough to show TOKAI OPTICAL’s high technological prowess. In September of the same year, we also developed a custom-ordered lens called the S-280D. As a “artisan” lens, it became a product that further appealed its technical capabilities. In 2009, Takeo Furuzawa assumed the post of chairman and Hirokazu Furuzawa assumed the post of president. I started running into a new era.

In April 2006, the world’s first and highest refractive index of 1.76 single focal plastic lens “Beluna ZX-AS” was released. In June of the same year, the world’s thinnest lens “Beluna ZX-MU” was released, attracting attention both in Japan and overseas. Both were extremely difficult to develop, but their high quality was enough to show TOKAI OPTICAL’s high technological prowess. In September of the same year, we also developed a custom-ordered lens called the S-280D. As a “artisan” lens, it became a product that further appealed its technical capabilities. In 2009, Takeo Furuzawa assumed the post of chairman and Hirokazu Furuzawa assumed the post of president. I started running into a new era. In 2010, TOKAI Shanghai was established. Established a local subsidiary and finally made inroads into China. In 2012, we exhibited for the first time at SIOF (Shanghai International Optical Exhibition). Since then, we have continued to exhibit, and at the SIOF held in February 2019, we exhibited TOKAI OPTICAL’s unique products such as “1.76 products”, “Lutina”, and “Hadabijin”, and received a great response.

In 2010, TOKAI Shanghai was established. Established a local subsidiary and finally made inroads into China. In 2012, we exhibited for the first time at SIOF (Shanghai International Optical Exhibition). Since then, we have continued to exhibit, and at the SIOF held in February 2019, we exhibited TOKAI OPTICAL’s unique products such as “1.76 products”, “Lutina”, and “Hadabijin”, and received a great response. President Takeo (current chairman) was struck by the information that Neuroscience was being used when tasting sake, and that was his first encounter with Neuroscience. Human subjectivity and what the brain perceives are not necessarily the same. Taking this as a hint, he contacted NTT Data Institute of Management Consulting, which is in charge of Neuroscience research, and began researching whether it was possible to evaluate progressive lenses using Neuroscience. As a result of various tests, it was found that the measurement results of brain waves could be reflected in the lens design, and a top-secret project was started.

President Takeo (current chairman) was struck by the information that Neuroscience was being used when tasting sake, and that was his first encounter with Neuroscience. Human subjectivity and what the brain perceives are not necessarily the same. Taking this as a hint, he contacted NTT Data Institute of Management Consulting, which is in charge of Neuroscience research, and began researching whether it was possible to evaluate progressive lenses using Neuroscience. As a result of various tests, it was found that the measurement results of brain waves could be reflected in the lens design, and a top-secret project was started. Neuroscience spectacle lenses have established a position both inside and outside the industry that is synonymous with “TOKAI OPTICAL is synonymous with Neuroscience.” After Beluna Resonas was announced, Resonas WS in 2009, Resonas Fit in 2010, Resonas MT and Resonus Fit WS in 2011, and the “Neuroscience Eyeglass Lens Series” were announced one after another. Furthermore, in collaboration with the National Institute for Physiological Sciences (Professor Ryusuke Kakinoki, Associate Professor Koji Inui), where the world’s most advanced Neuroscience research is being conducted, we announced the “Beluna Resonas Presso”, a progressive lens for near and middle ages. It has been evaluated as the latest Neuroscience that is also valuable from the point of view. In 2013, we developed the “Beluna Granas”, a progressive lens that looks optimal when viewed with both eyes by evaluating the lens with a magnetoencephalogram (MEG). In the following year, we released the Beluna Neurogran, which introduced an original optimal correction system that matched the individuality of each individual’s eyes. In this way, 10 years after its birth, the neuroscience eyeglass lens series has expanded to 17 products. In 2018, we announced the culmination of our efforts, “Resonas X (Ten),” and realized a lens with a “comfortable wearing feeling that extends to the brain,” incorporating all of our previous technologies.

Neuroscience spectacle lenses have established a position both inside and outside the industry that is synonymous with “TOKAI OPTICAL is synonymous with Neuroscience.” After Beluna Resonas was announced, Resonas WS in 2009, Resonas Fit in 2010, Resonas MT and Resonus Fit WS in 2011, and the “Neuroscience Eyeglass Lens Series” were announced one after another. Furthermore, in collaboration with the National Institute for Physiological Sciences (Professor Ryusuke Kakinoki, Associate Professor Koji Inui), where the world’s most advanced Neuroscience research is being conducted, we announced the “Beluna Resonas Presso”, a progressive lens for near and middle ages. It has been evaluated as the latest Neuroscience that is also valuable from the point of view. In 2013, we developed the “Beluna Granas”, a progressive lens that looks optimal when viewed with both eyes by evaluating the lens with a magnetoencephalogram (MEG). In the following year, we released the Beluna Neurogran, which introduced an original optimal correction system that matched the individuality of each individual’s eyes. In this way, 10 years after its birth, the neuroscience eyeglass lens series has expanded to 17 products. In 2018, we announced the culmination of our efforts, “Resonas X (Ten),” and realized a lens with a “comfortable wearing feeling that extends to the brain,” incorporating all of our previous technologies. Taking the opportunity of iOFT2014 in 2014, TOKAI OPTICAL launched the concept of manufacturing to protect the health of the eyes: “Protect your eyes from light more to stay healthy. Eye care design that creates future standards.” . The first lens that embodies this is the new product “Lutina”. Focusing on “lutein” present in the “macula”, which is important for seeing things, we have developed a lens that reduces consumption of lutein by cutting light. The differentiation and new concept of eye health has been accepted in the market and recognized as TOKAI OPTICAL’s main brand. A major pillar of TOKAI OPTICAL is the unique manufacturing that creates new value that has yet to be seen in the industry with such technological and development capabilities that cannot be imitated by other companies.

Taking the opportunity of iOFT2014 in 2014, TOKAI OPTICAL launched the concept of manufacturing to protect the health of the eyes: “Protect your eyes from light more to stay healthy. Eye care design that creates future standards.” . The first lens that embodies this is the new product “Lutina”. Focusing on “lutein” present in the “macula”, which is important for seeing things, we have developed a lens that reduces consumption of lutein by cutting light. The differentiation and new concept of eye health has been accepted in the market and recognized as TOKAI OPTICAL’s main brand. A major pillar of TOKAI OPTICAL is the unique manufacturing that creates new value that has yet to be seen in the industry with such technological and development capabilities that cannot be imitated by other companies. In 2011, in the midst of calls to promote the active participation of women, an all-female product development team, “Joshikai,” was established with the aim of differentiating itself from other companies by developing new products from a female perspective. From development to sales, an all-female team worked, and in 2012, the first Joshikai original product “Hadabijin” was announced. Introduced personal color theory to lens development and held experience-based seminars nationwide. We adopted a sales support method in which employees with personal color advisor qualifications directly coordinate eyeglasses for customers. This was well received, and in 2013, the second product “Handsome Man” was released, and in addition, “Hadabijin +”, which was also involved in the development of eyeglass frames, was released, and the series became a big hit. After that, the members of Joshikai will continue to make great strides. In order to investigate the scientific basis that color brings to the human body, we enlisted the cooperation of a medical doctor who is familiar with color psychotherapy and conducted a clinical trial. As a result, many people responded that the pink wavelength refreshed their feelings and made them brighter. Based on that, we developed pink sunglasses “Bibi Pink”. This was picked up by various media such as NHK, and was selected as an excellent winning idea in the “Healthcare Brain Challenge” of the Cabinet Office’s Impulsing Transformational Research and Development Program (ImPACT).

In 2011, in the midst of calls to promote the active participation of women, an all-female product development team, “Joshikai,” was established with the aim of differentiating itself from other companies by developing new products from a female perspective. From development to sales, an all-female team worked, and in 2012, the first Joshikai original product “Hadabijin” was announced. Introduced personal color theory to lens development and held experience-based seminars nationwide. We adopted a sales support method in which employees with personal color advisor qualifications directly coordinate eyeglasses for customers. This was well received, and in 2013, the second product “Handsome Man” was released, and in addition, “Hadabijin +”, which was also involved in the development of eyeglass frames, was released, and the series became a big hit. After that, the members of Joshikai will continue to make great strides. In order to investigate the scientific basis that color brings to the human body, we enlisted the cooperation of a medical doctor who is familiar with color psychotherapy and conducted a clinical trial. As a result, many people responded that the pink wavelength refreshed their feelings and made them brighter. Based on that, we developed pink sunglasses “Bibi Pink”. This was picked up by various media such as NHK, and was selected as an excellent winning idea in the “Healthcare Brain Challenge” of the Cabinet Office’s Impulsing Transformational Research and Development Program (ImPACT). In 2016, an engineer from TOKAI OPTICAL took second place at the design contest of the International Conference on Optical Thin Films (OIC) held in Arizona, USA. He has deepened exchanges with experts, researchers, and engineers in the field of optical thin films, and has become a driving force behind TOKAI OPTICAL’s technological capabilities. Furthermore, in 2018, the optical sensor concentrator developed and manufactured by the Optical Function Division was adopted by the Institute for Cosmic Ray Research, the University of Tokyo, for the Cherenkov Telescope Array, one of the world’s largest gamma-ray observatories in the Spanish Canary Islands. installed. The fact that they relied on TOKAI OPTICAL’s technical capabilities in the field of cosmic ray research, an international joint project that requires high technology, once again led to their confidence and pride in their own technology.

In 2016, an engineer from TOKAI OPTICAL took second place at the design contest of the International Conference on Optical Thin Films (OIC) held in Arizona, USA. He has deepened exchanges with experts, researchers, and engineers in the field of optical thin films, and has become a driving force behind TOKAI OPTICAL’s technological capabilities. Furthermore, in 2018, the optical sensor concentrator developed and manufactured by the Optical Function Division was adopted by the Institute for Cosmic Ray Research, the University of Tokyo, for the Cherenkov Telescope Array, one of the world’s largest gamma-ray observatories in the Spanish Canary Islands. installed. The fact that they relied on TOKAI OPTICAL’s technical capabilities in the field of cosmic ray research, an international joint project that requires high technology, once again led to their confidence and pride in their own technology.