Solar power generation facility

The implementation of renewable energy from solar power generation started from March 2024. The power generation output of 450kw (on sunny days) supplements part of the power used by the Shinpukuji Factory.

TOKAI OPTICAL Group will accelerate the reduction of CO2 emissions by implementing measures to improve energy efficiency and expanding solar power generation, which are part of the “Aiming for symbiosis and harmony with the natural environment, we will work on environmental load reduction and environmental conservation,” an environmental measure set forth in the “TOKAI OPTICAL Group SDGs Declaration” .

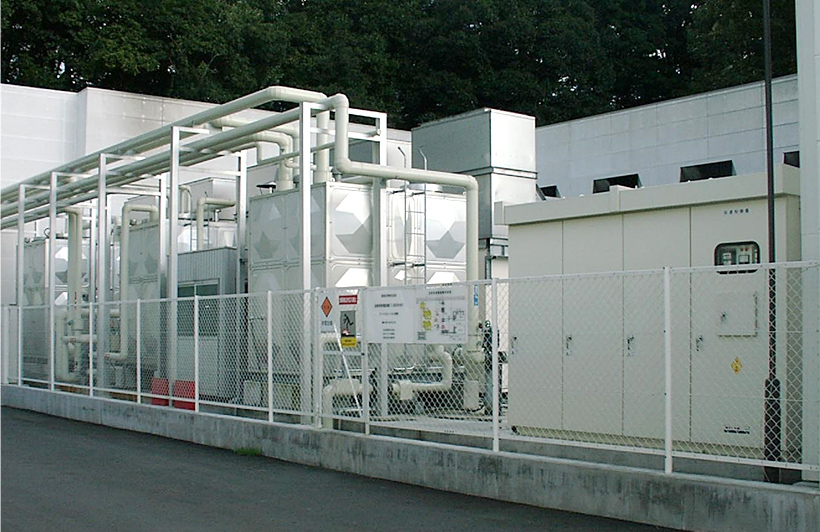

In-house power generation facility

In April 2003, we introduced a cogeneration system equipped with 10 diesel engine generators with an output of 185 kW and an adsorption chiller that extracts energy from waste heat as well as power generation with the aim of reducing the air conditioning load and CO2 emissions. Currently, it is used for power peak cut. Immediately after the Great East Japan Earthquake, we lent out this diesel engine generator to help with reconstruction support.

Desiccant dehumidifier

This is a “desiccant dehumidifier” that maintains dehumidified air conditioning at around 25°C throughout the year in a clean room.In 2016, we upgraded to a CO2 heat pump type desiccant dehumidifier that does not use Freon refrigerant, which contributes to the destruction of the ozone layer. By stopping the boiler, which had been necessary until then, and by using the latest equipment to further stabilize and improve room temperature and humidity through energy-saving effects, we were able to reduce CO2 emissions by 237.7 t/year .

Direct cooler

We have installed a “direct cooler” that blows cool air into the factory while removing odors and dust inside the factory to reduce the load on the air conditioner.

Wastewater treatment facility

In October 2001, we began operating a wastewater treatment facility with approximately twice the processing capacity of the previous facility. We have switched to in-house processing of detergents and dyeing waste liquids, which had previously been processed externally . a strict monitoring system with automatic measurement equipment. Wastewater from the factory is discharged into public water areas in accordance with our own standards that exceed the national government, Okazaki City ordinances in Aichi Prefecture, and the Yahagi River system wastewater standards . 20㎥/day is reused as reclaimed water in the production process.

Purified water facility

In October 2004, we introduced purification treatment facilities at the head office factory and in May 2016 at the Shinpukuji office in order to promote the recycling of water after wastewater treatment . regional water resources) by approximately 250㎥/day.

Legal compliance

TOKAI OPTICAL complies with laws and social norms.

We hold monthly meetings of the Management and Legal Affairs Committee to ascertain information on laws and regulations and revisions and manage the latest versions . the workplace is also checked for contamination of groundwater, soil, etc., and environmental impacts such as odor and air pollution in the vicinity of the factory.

Furthermore, in order to promote environmental activities, we believe that it is necessary to raise the environmental awareness of each and every employee, and based on our environmental policy, we conduct environmental education, enlightenment activities, and emergency response drills . are made aware of easy-to-understand explanations of laws on the intranet.