Durability and Low Reflection combined

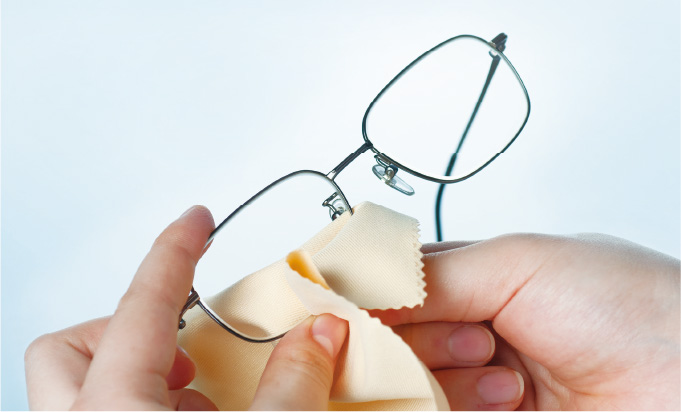

In addition to ease of handling, comfort, and durability in daily use as eyeglasses, the “Ultra Shield Performance” is also focused on the appearance of the glasses.

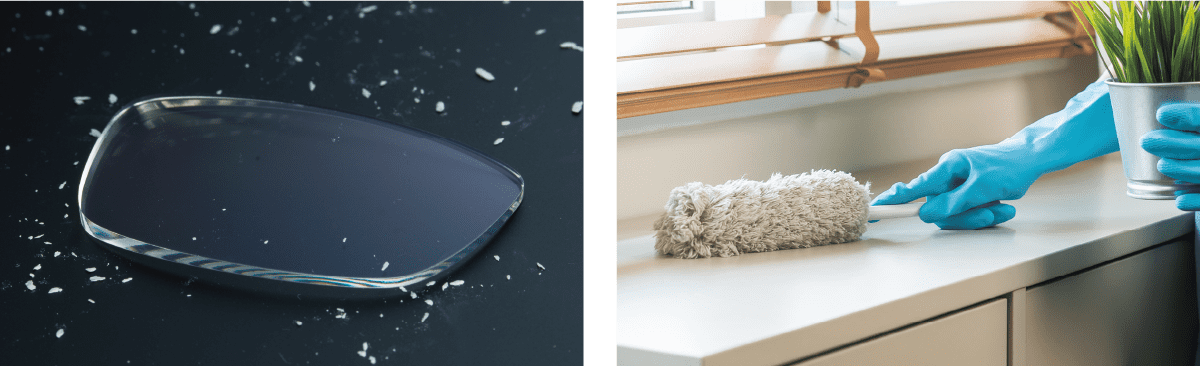

It is comfortable and resistant to scratches, dirt, and dust.

At the same time it can provide beautiful perception when viewed by others.

The greatest strength of “Ultra Shield Performance” is the high-hardness hard coating made with high molecular density and hybridized molecules and particles. With the high-density multi-coating combined the coating has realized improved scratch resistance and durability.

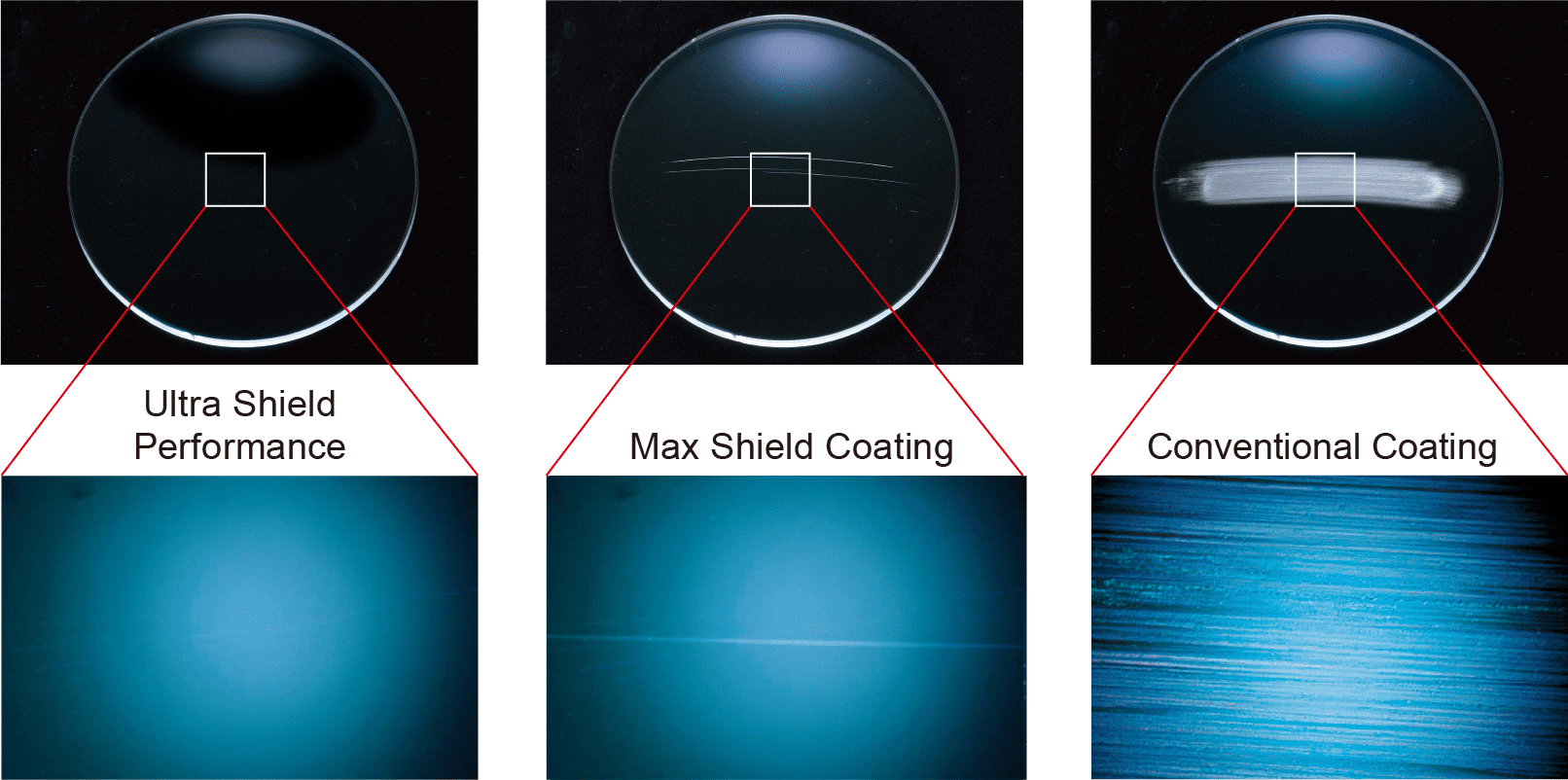

Improved scratch resistance for peace of mind!

Approximately 2 times* more scratch-resistant than Max Shield Coating.

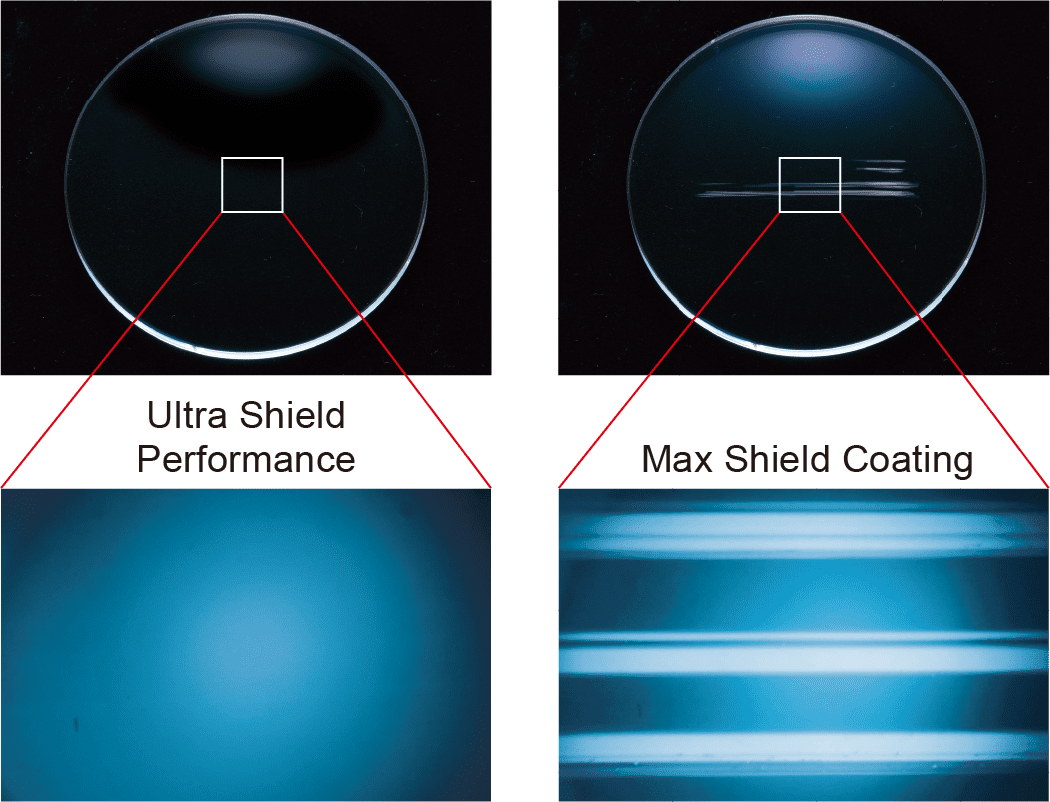

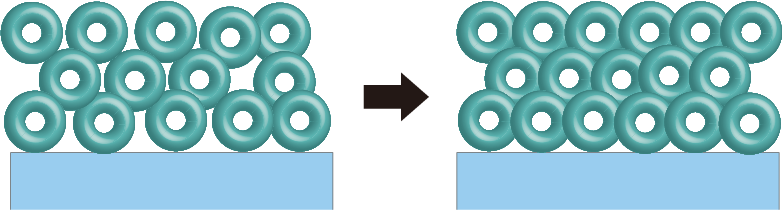

Scratch-resistant and long-lasting even after long-term use!

The scratch resistance performance does not degrade even after the ccelerated weathering test.

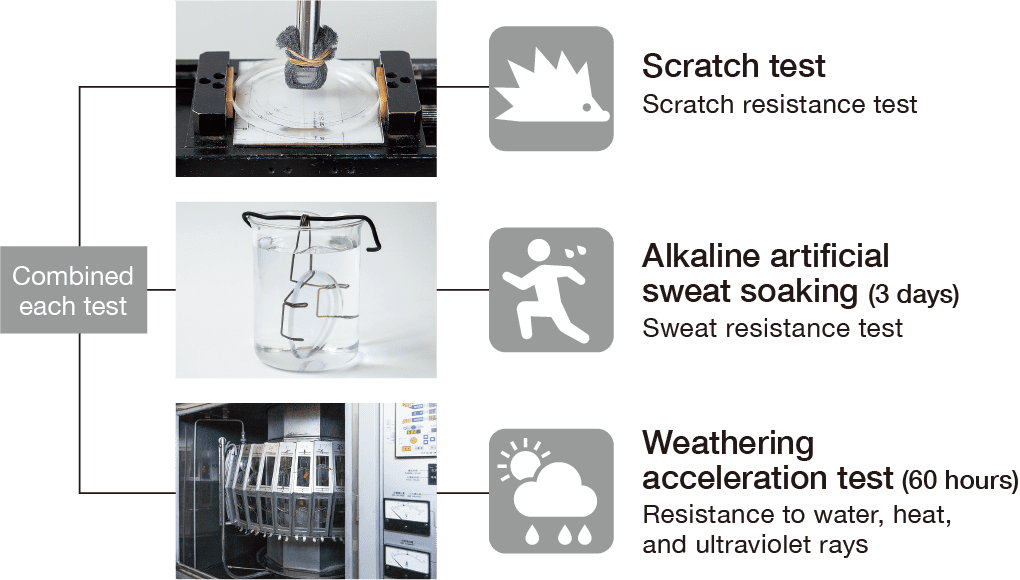

TOKAI’s proprietary

scratch manifestation test

Minute scratches caused by daily care and external factors are enlarged by ultraviolet rays, heat, water, and sweat in daily life and become visible scratches. Therefore, we devised an original test method that assumes daily use. As a result, we have developed a scratch-resistant and durable lens coating that can withstand harsh conditions.

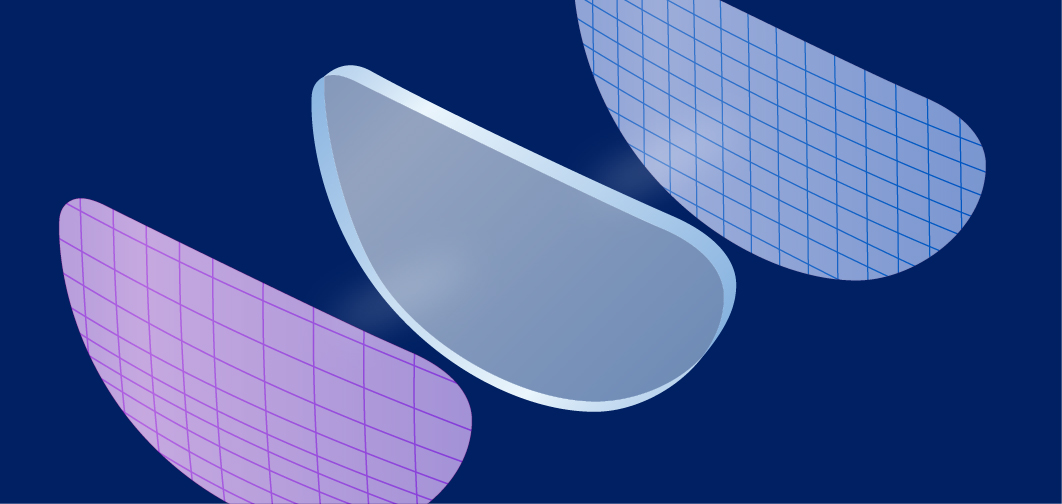

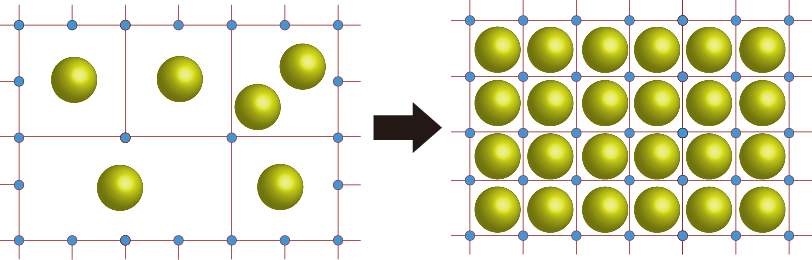

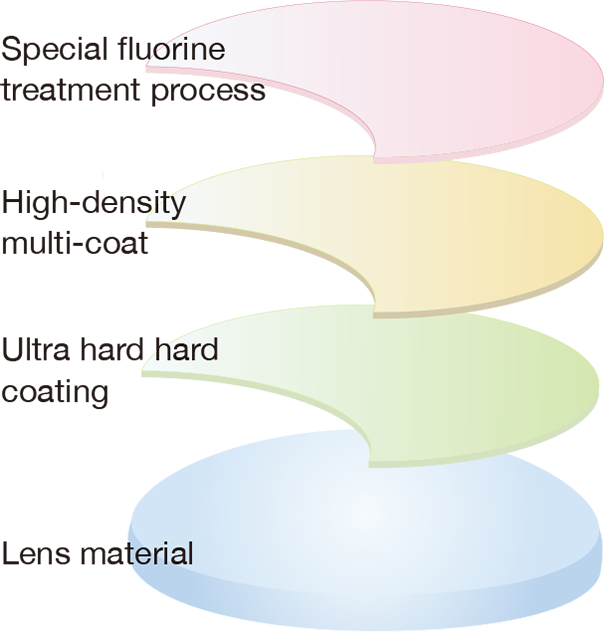

Reasons for the strength of Ultra Shield Performance

Ultra hard hard coating

Unparalleled scratch resistance is realized by increasing hardness through molecular densification and hybridization of molecules and fine particles.

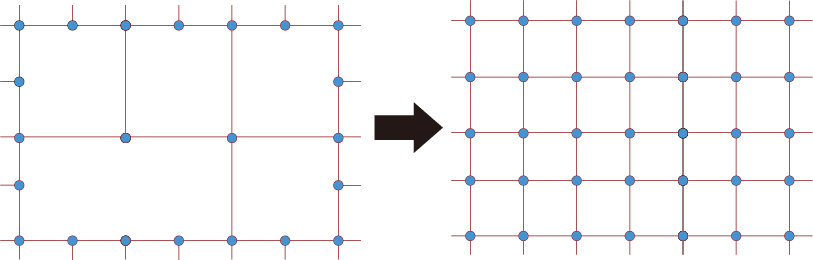

High-density multi-coat

The higher density multi coating improves hardness, making it scratch-resistant even under harsh conditions.

Special fluorine treatment process

The fluorine treatment makes low coefficient of friction and does not apply extra load when wiping lenses, making them scratch resistant.

Coating Structure

Glasses shine in web conferencing.

Because it is through a screen, it is necessary to make a beautiful impression on the other party.

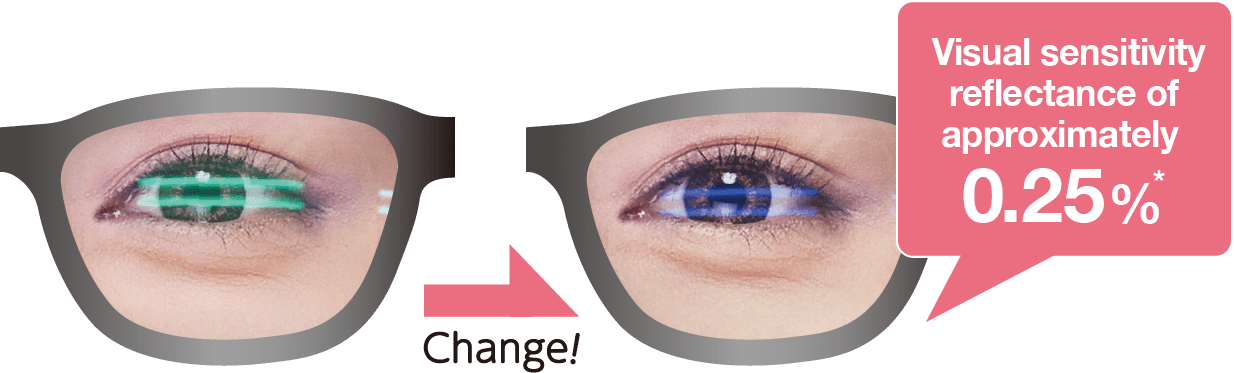

Reduced reflectivity compared to conventional lenses.

Reflected light is suppressed and the eyes appear clearer.

Reduces visible reflections!

A new standard focusing on visual sensitivity, achieving a visual sensitivity reflectance of approximately 0.25%*.

The eyes look beautiful when viewed by others or through a monitor.

This value is not the value specified by the manufacturer according to JIST 7334.

Stain-resistant and easy to clean!

High water and oil repellency with excellent stain resistance performance, it is stain resistant and easy to wipe off.

Dust-resistant and comfortable!

The anti-static function prevents dust from sticking to the surface, making it easy to clean.

- *Compared to our company with 1.60 material lens *Even coated lenses with improved scratch resistance and durability may become scratched or the coating may crack due to excessive impact or handling.

- *All comparison photos are based on our company’s comparison with lenses made of material with a refractive index of 1.60. *Spectral characteristics may vary depending on the material and coating.

- *The actual color differs due to printing conditions. *All photos and illustrations are for illustrative purposes only.